The lap joint flange is used widely in common piping systems, what is the advantage of the lap joint flange ?

1. Because of the structure of a Lap joing flange , it can swivel around the stub end and pipe lining. When the piping system is assembe and disassemble frequently, it is better to use a Lap joint flange. It means the flange can work even the two flanges bolt holes are misalignment .

2. In a corrosive situation, the flange joints need to be exchange very soon. To a lap joint flange, only the stub end is touch with the pipe and fluid , the backing flange no need to touch it . It means you could only replace the stub end , no need to replace the backing flange , so the lap joint flange can decrease the cost of the piping systems.

3. The backing flange and the stub end is seperated , so we can use two different materials for the two pieces. it can work for more complicated application.

Standard

1.ASME

ANSI B16.5,ASME B16.5,ASME B16.47,ASME B16.36,ASME B16.48,AWWA C-207,API 605,API590,MSS SP44,API6A

2.DIN

DIN2527,DIN2566,DIN2573,DIN2576,DIN2627,DIN2628,DIN2629,DIN2630,DIN2631,DIN2632,

DIN2633,DIN2634,DIN2635,DIN2636,DIN2637,DIN2638,DIN2641,DIN642,DIN2655,DIN2656,

DIN2673,DIN28030,DIN28031,DIN28032,DIN28036,DIN28038,DIN86029,DIN86030,DIN11864-2

3.EN

EN1092-1,EN1759-1

4.BS

B.S 3293,B.S 4504,B.S 10

5.ISO

ISO 7005-1

6.AS

AS2129,AS4087, AS, NZS 4331.1

7.JIS

JIS B2220,JIS B2238,JIS B2290,JIS G3443-2,JPI-7S-15,JPI-7S-43

8.UNI

UNI2253,UNI2254,UNI2276,UNI2277,UNI2278,UNI2280,UNI,2281~2286,UNI6091~6094

Size

1,8”~160”,DN10~DN4000

Pressure

PN1,PN2.5,PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160,PN250,PN320,PN400

CLASS75,CLASS150,CLASS300,CLASS400,CLASS600,CLASS900,CLASS1500,CLASS2500

2K,5K,10K,16K,20K,30K,40K

Specification

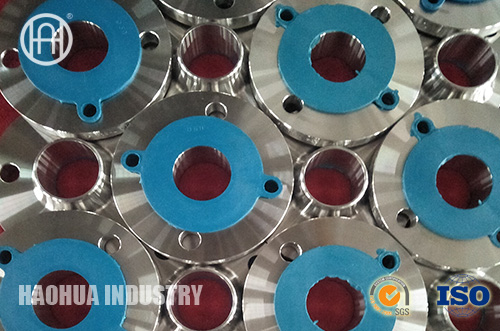

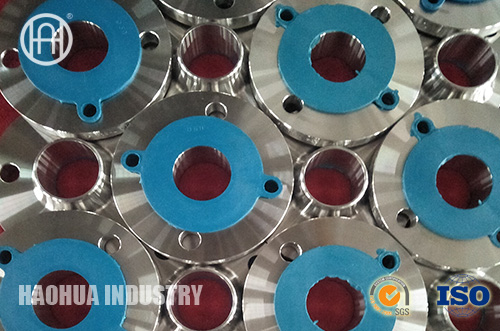

Plate Flange,Slip-On Welding Flange,Welding Neck Flange,Threaded Flange,Socket Welding Flange,Blind Flange,Long Welding Neck Flange,Lap Joint,Loose Plate Flange,Orifice Flange,Reducing Flange,Integral flange,Figure-8,Paddle Blank,Paddle Spacer,Specatcle Blind,Squre Flange,Reducing Flange, Orifice Flange

Material

1.Carbon Steel

A105,A350 LF1,A350 LF2,A350 LF3

2.Stainless Steel

ASTM SA-182/SA-182M F304,F304H,F304L,F316,F316H,F316L,F321,321H,F316Ti,317,F317H,F347,F904L,F310

3.Duplex Steel

F51,F53,F60

4. Hastelloy

Hastelloy B,Hastelloy B-2,Hastelloy B-3,Hastelloy C-4,Hastelloy C-22,,Hastelloy C-276,Hastelloy C-2000,Hastelloy G-35,Hastelloy G-30,Hastelloy N,Hastelloy S,Hastelloy X

5. Haynes

Haynes 188,Haynes 230,Haynes 556

6. Incoloy

Incoloy 020,Incoloy 800,Incoloy 800H,Incoloy 800HT,Incoloy 825,Incoloy 925,Incoloy A-286,

7. Inconel

Inconel 600,Inconel 601,Inconel 617,Inconel 625,Inconel 718,Inconel X750

8. Monel

Monel 400,Monel 401,Monel 404,Monel K-500

9. Nickel

Nickel 200,Nickel 201