Orifice Flanges are used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Pairs of pressure "Tappings", mostly on 2 sides, directly opposite each other, are machined into the orifice flange. This makes separate orifice carriers or tappings in the pipe wall unnecessary.

Orifice Flanges generally come with either Raised Faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, the same as weld neck and slip on flanges with extra machining.

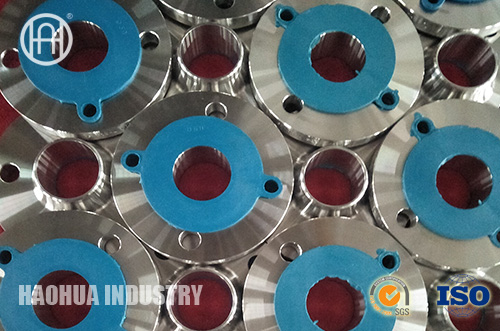

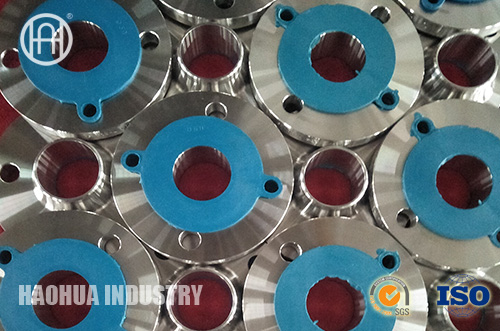

The image on the right shows a set Orifice Flanges, where a Orifice Plate is mounted and a jack screw is machined. This jack screw is used to facilitate separating the flanges for inspection or replacement of the Orifice Plate and gaskets.

The range of orifice flanges covers all standard sizes and ranges, and all common flange materials. Flanges are available in Welding Neck, Slip On, and Threaded form, and are typically supplied with two 1/2" NPT tappings in each flange.

ASME B16.36 covers Dimensions and dimensional tolerances from orifice flanges (similar to those covered in ASME B16.5) that have orifice pressure differential connections. Coverage is limited to the following flanges:

WELDING NECK CLASSES 300, 400, 600, 900, 1500, 2500

SLIP ON CLASS 300

THREADED CLASS 300

1.ASME

ANSI B16.5,ASME B16.5,ASME B16.47,ASME B16.36,ASME B16.48,AWWA C-207,API 605,API590,MSS SP44,API6A

2.DIN

DIN2527,DIN2566,DIN2573,DIN2576,DIN2627,DIN2628,DIN2629,DIN2630,DIN2631,DIN2632,

DIN2633,DIN2634,DIN2635,DIN2636,DIN2637,DIN2638,DIN2641,DIN642,DIN2655,DIN2656,

DIN2673,DIN28030,DIN28031,DIN28032,DIN28036,DIN28038,DIN86029,DIN86030,DIN11864-2

3.EN

EN1092-1,EN1759-1

4.BS

B.S 3293,B.S 4504,B.S 10

5.ISO

ISO 7005-1

6.AS

AS2129,AS4087, AS, NZS 4331.1

7.JIS

JIS B2220,JIS B2238,JIS B2290,JIS G3443-2,JPI-7S-15,JPI-7S-43

8.UNI

UNI2253,UNI2254,UNI2276,UNI2277,UNI2278,UNI2280,UNI,2281~2286,UNI6091~6094

Size

1/8”~160”,DN10~DN4000

Pressure

PN1,PN2.5,PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160,PN250,PN320,PN400

CLASS75,CLASS150,CLASS300,CLASS400,CLASS600,CLASS900,CLASS1500,CLASS2500

2K,5K,10K,16K,20K,30K,40K

Specification

Plate Flange,Slip-On Welding Flange,Welding Neck Flange,Threaded Flange,Socket Welding Flange,Blind Flange,Long Welding Neck Flange,Lap Joint,Loose Plate Flange,Orifice Flange,Reducing Flange,Integral flange,Figure-8,Paddle Blank,Paddle Spacer,Specatcle Blind,Squre Flange,Reducing Flange, Orifice Flange

Material

1.Carbon Steel

A105,A350 LF1,A350 LF2,A350 LF3

2.Stainless Steel

ASTM SA-182/SA-182M F304,F304H,F304L,F316,F316H,F316L,F321,321H,F316Ti,317,F317H,F347,F904L,F310

3.Duplex Stainless Steel

F51,F53,F60

4. Hastelloy

Hastelloy B,Hastelloy B-2,Hastelloy B-3,Hastelloy C-4,Hastelloy C-22,,Hastelloy C-276,Hastelloy C-2000,Hastelloy G-35,Hastelloy G-30,Hastelloy N,Hastelloy S,Hastelloy X

5. Haynes

Haynes 188,Haynes 230,Haynes 556

6. Incoloy

Incoloy 020,Incoloy 800,Incoloy 800H,Incoloy 800HT,Incoloy 825,Incoloy 925,Incoloy A-286,

7. Inconel

Inconel 600,Inconel 601,Inconel 617,Inconel 625,Inconel 718,Inconel X750

8. Monel

Monel 400,Monel 401,Monel 404,Monel K-500

9. Nickel

Nickel 200,Nickel 201